Description

When it comes to selecting the finest Ball Valve, King Valves India stands out as a top choice. Renowned for our advanced design and superior performance, King’s Ball Valve offers longevity and reliability. Ideal for high-pressure and temperature environments, our valves are trusted for critical applications like hydrocarbons, cryogenic services, and more.

With a focus on durability and versatility, our Ball Valve excels in various industries. Plus, our commitment to exceptional service ensures a satisfying experience for our customers. Once you experience the quality and efficiency of King’s Ball Valve, you’ll see why we’re the preferred choice.

Customers seeking reliable Ball Valve, backed by excellent service would likely find King Valves India to be a trusted partner. It’s reassuring to know that once you’ve experienced their products, you may not feel the need to look elsewhere for Ball Valve, solutions.

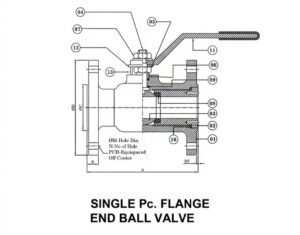

A single-Piece Ball Valve

A single-piece ball valve, also known as a one-piece ball valve, is a type of ball valve where the body is made from a single, continuous piece of material. This design contrasts with multi-piece valves, which are constructed from multiple separate components. Here’s a detailed overview of its features, advantages, and applications.

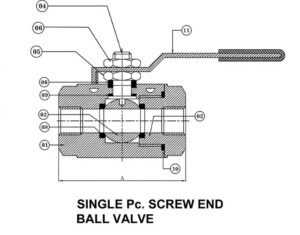

A single-Piece Ball Valve With Screw (threaded) and Socket Weld Ends

A single-piece ball valve with screw (threaded) and socket weld ends is a type of ball valve designed to offer a combination of end connection options with the robustness of a single-piece body construction. Here’s a detailed breakdown of what this entails

Components and Features

Single-Piece Body

- Construction: The body of the valve is made from a single, continuous piece of material. This design eliminates seams or joints in the valve body, which can enhance durability and reduce the potential for leaks.

- Material: Typically made from materials like brass, stainless steel, or plastic, depending on the application and fluid compatibility.

End Connections

Screw (Threaded) Ends

- Description: Threaded ends allow the valve to be screwed directly into threaded pipe fittings. This provides a secure connection without the need for additional flanges or welding.

- Advantages: Ease of installation and removal, cost-effectiveness, and suitability for lower pressure and temperature applications.

Socket Weld Ends

- Description: Socket weld ends are designed for welding the valve to the pipe. The valve’s end is inserted into a socket on the pipe, and the connection is made by welding, providing a strong, permanent seal.

- Advantages: Provides a robust, leak-proof connection ideal for high-pressure and high-temperature applications. This design is also durable and resistant to vibration.

Advantages

Flexibility

- Versatility: Allows the valve to be used in systems where different types of connections are required. For example, it may have a threaded connection on one end and a socket weld connection on the other end, enabling integration with various pipeline configurations.

Installation and Maintenance

- Ease of Installation: Threaded connections simplify installation and removal, while socket weld connections offer a permanent seal for high-pressure applications.

- Maintenance: The single-piece design reduces the number of potential failure points and simplifies maintenance by providing a more robust construction.

Applications

Residential Plumbing

Used for water supply and drainage systems where simplicity and cost-effectiveness are key.

- Oil and Gas: Suitable for pipelines requiring different types of connections, such as threaded and welded sections.

Industrial Processes

Suitable for applications with moderate pressures and temperatures where the robust, simple design is advantageous.

- Chemical Processing: Used where different pipe fittings are needed, and robust connections are necessary for handling corrosive or high-temperature fluids.

- Water and Wastewater Treatment: Useful in systems with varying pipe connections and where durability and reliability are important.

- HVAC Systems: Provides flexibility in connecting different types of pipe fittings while managing fluid flow.

Food and Beverage

Used in industries where hygiene and cleanliness are important, often made from stainless steel to meet sanitary requirements.

Considerations

Limited Size and Pressure Range

Single-piece ball valves are generally used for smaller sizes and lower pressures compared to multi-piece or flanged ball valves.

Replacement of Internal Parts

Because the body is a single piece, if internal components like the ball or seats fail, the entire valve typically needs to be replaced.

- Material Compatibility: Ensure that the valve material is suitable for the fluids being handled and the operating conditions.

- Installation Requirements: Socket weld ends require welding, which needs proper equipment and skilled labor. Threaded ends offer easier installation but are generally used for lower pressure applications.

- Maintenance: While the single-piece design is durable, if internal components like the ball or seats fail, the entire valve may need to be replaced.

In summary, a single-piece ball valve with screw and socket weld ends offers a combination of versatility and robustness. Its single-piece body construction provides enhanced durability, while the various end connections offer flexibility for different installation scenarios. This design is well-suited for a range of applications where both threaded and welded connections are needed.

Reviews

There are no reviews yet.