Description

When selecting the finest Ball Valve, King Valves India stands out as a top manufacturer and supplier in India. Renowned for our advanced design and superior performance, King ‘s Ball Valve offers longevity and reliability. Ideal for high-pressure and temperature environments, our valves are trusted for critical applications like hydrocarbons, cryogenic services, and more.

With a focus on durability and versatility, our Ball Valve excels in various industries. Plus, our commitment to exceptional service ensures a satisfying experience for our customers. Once you experience the quality and efficiency of King’s Ball Valve, you’ll see why we’re the preferred choice.

Customers seeking reliable Ball Valve, backed by excellent service would likely find King Valves India to be a trusted partner. It’s reassuring to know that once you’ve experienced their products, you may not feel the need to look elsewhere for Ball Valve solutions.

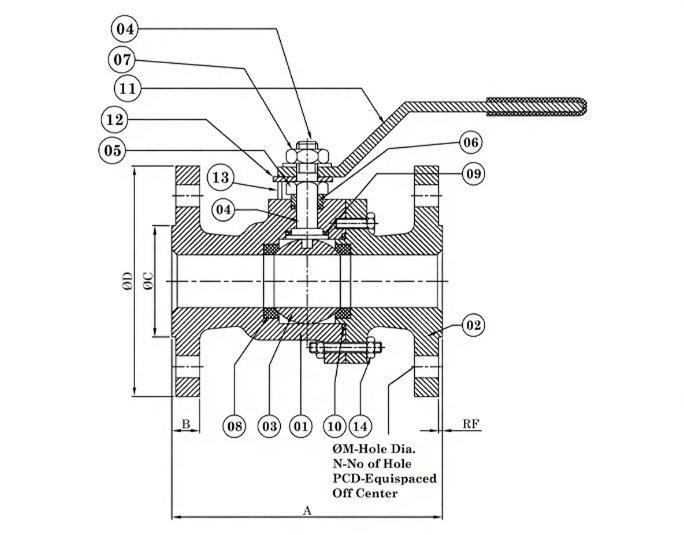

A two-piece ball valve is a type of ball valve that features a body consisting of two main parts: a central body and two end pieces. This design is commonly used in various industrial and commercial applications due to its simplicity and effectiveness. Here’s a detailed overview of its components and features:

Components

Body

- Central Body Section: This is the primary part of the valve that contains the ball and internal mechanisms. The central body houses the flow path and the ball, which controls the fluid flow.

- End Pieces: The two end pieces are attached to the central body section and are typically bolted or screwed into place. These end pieces connect the valve to the piping system.

Ball

- A spherical component with a hole or port through its center. The ball rotates to control the flow of fluid when the hole is aligned with the flow path, the valve is open; when it is perpendicular to the flow path, the valve is closed.

Stem

- The stem connects the ball to the actuator (manual handle or motor). It transmits the rotational motion from the actuator to the ball.

Seats

- Sealing components located on either side of the ball. Seats are designed to provide a tight seal when the valve is closed, preventing leaks. They are typically made from materials like Teflon (PTFE) or other elastomers.

Considerations

- Material Compatibility: Ensure that the valve material is compatible with the fluid being handled, especially in corrosive or high-temperature environments.

- Leakage and Sealing:The effectiveness of the seal is crucial. Proper maintenance is required to ensure that the seats continue to provide a leak-proof seal.

Applications

- Water and Wastewater Treatment: Used to control the flow of water and treatment chemicals in municipal and industrial systems.

- HVAC Systems: Commonly used in heating, ventilation, and air conditioning systems to regulate fluid flow.

- Oil and Gas: Employed in pipelines and processing systems to manage the flow of hydrocarbons and other fluids.

- Chemical Processing: Used to handle a variety of chemicals, with careful selection of materials to ensure compatibility with the fluids being managed.

Advantages

- Simplicity: The two-piece design is straightforward and often less expensive than more complex valve designs. It consists of fewer components, which can simplify manufacturing and assembly.

- Ease of Maintenance: While it has fewer parts than a three-piece valve, the two-piece valve design allows for relatively easy maintenance. In some cases, the valve can be disassembled for servicing by removing the end pieces.

- Compact Design: The two-piece ball valve generally has a more compact design compared to a three-piece ball valve, making it suitable for applications with space constraints.

- Cost-Effective: Often less expensive than three-piece or flanged valves, making it a cost-effective choice for many applications.

In summary, a two-piece ball valve is valued for its straightforward design, ease of maintenance, and cost-effectiveness. Its design allows it to handle a variety of fluids and applications efficiently, though it may be less adaptable than a three-piece valve when it comes to maintenance or servicing without removing the entire valve from the pipeline.

Reviews

There are no reviews yet.