Description

When selecting the finest Ball Valve, King Valves India stands out as a top manufacturer and supplier in India. Renowned for our advanced design and superior performance, King Valve’s three-piece ball valve and 3pcs ball valve offer longevity and reliability. Ideal for high-pressure and temperature environments, our valves are trusted for critical applications like hydrocarbons, cryogenic services, and more.With a focus on durability and versatility, our Ball Valve excels in various industries. Plus, our commitment to exceptional service ensures a satisfying experience for our customers. Once you experience the quality and efficiency of King’s Ball Valve, you’ll see why we’re the preferred choice.

Customers seeking reliable Ball Valve, backed by excellent service would likely find King Valves India to be a trusted partner. It’s reassuring to know that once you’ve experienced their products, you may not feel the need to look elsewhere for Ball Valve solutions.

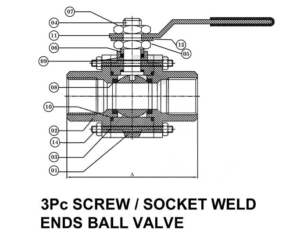

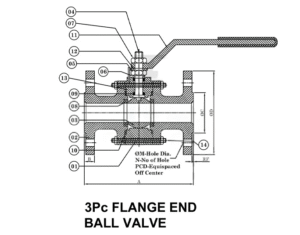

A Three-Piece Ball Valve

A Three-Piece Ball Valve is a type of valve used to control the flow of fluids in a pipeline. It is called a “three-piece” valve because its construction consists of three main components. These valves are available in various configurations, 3pc screw/socket weld end ball valves, and 3pcs flange end ball valves, each offering versatility and reliability for different piping needs.

Advantages

Modularity: The modular design allows for the replacement of worn-out or damaged parts without having to replace the entire valve, which can be more cost-effective.

Ease of Maintenance

- The three-piece design allows for easy disassembly of the valve into its three main parts, making it straightforward to access and replace internal components (like the ball or seats) without removing the entire valve from the pipeline.

Versatility

- It can be used in a wide range of applications, including those involving high pressure and high temperature. It is available in various sizes and materials to handle different types of fluids.

Durability

- Designed to withstand harsh operating conditions, making it suitable for demanding environments in industrial processes.

Leak-Proof Operation

- The design provides a reliable seal with minimal leakage, thanks to its multiple sealing surfaces and robust construction.

Flexibility in Installation: The combination allows for flexibility in installing the valve in various pipeline configurations, accommodating different piping systems and installation requirements.

Applications

- Oil and Gas: For controlling the flow of crude oil, natural gas, and other hydrocarbons in pipelines and processing systems.

- Chemical Processing: To handle corrosive and abrasive chemicals safely and effectively.

- Water and Wastewater Treatment: In systems that regulate the flow of water and treatment chemicals.

- HVAC Systems: For managing fluid flow in heating, ventilation, and air conditioning systems.

Components

Body

- Central Body Section: This part of the valve houses the ball and internal mechanisms. It contains the main flow path and is where the ball rotates to control the flow.

- End Pieces (or End Caps): These are two separate pieces that are bolted or connected to the central body section. They are responsible for connecting the valve to the pipeline and can be removed to access the internal components.

Ball

- The spherical component inside the valve has a hole or port through its center. The ball rotates to either allow or block the flow of fluid. When the port aligns with the flow path, the valve is open; when it is perpendicular to the flow path, the valve is closed.

Stem

- The stem connects the ball to the actuator (manual handle or automated mechanism). It transmits the rotational motion from the actuator to the ball, enabling it to open or close the valve.

Seats

- These are sealing components located on either side of the ball. They are typically made from materials such as Teflon (PTFE) or other elastomers and ensure a tight seal when the valve is closed, preventing leaks.

A Three-Piece Ball Valve With Screw (Threaded) and Socket Weld Ends

Combines The characteristics of a three-piece ball valve with two different types of end connections. Here’s a detailed explanation of what it entails.

Connections

Screw (Threaded) Ends

- Threaded Ends: These are standard male or female threads on the ends of the valve body that allow it to be screwed into threaded pipe fittings. This provides a secure connection without the need for welding or additional flanges.

- Advantages: Ease of installation and removal, cost-effectiveness, and suitability for lower pressure applications.

Socket Weld Ends

- Socket Weld Ends: The valve ends are designed to fit into a socket on the pipe. The connection is made by welding the valve to the pipe, providing a strong, permanent seal.

- Advantages: Provides a leak-proof connection ideal for high-pressure and high-temperature applications. It is also robust and durable.

Considerations

- Material Compatibility: Ensure that the valve material is compatible with the fluids being handled and the operating conditions.

- Installation Requirements: Threaded ends are easier to install, while socket weld ends require welding equipment and skilled labor.

- Construction: The valve consists of a central body with two end pieces that can be bolted on or off. This allows for straightforward installation and replacement of the valve.

- Maintenance: Maintenance is facilitated by the ability to remove the end pieces without removing the valve from the pipeline. This access allows for the replacement of internal components like the ball and seats.

In summary, a three-piece ball valve with screw and socket weld ends combines the advantages of both connection types, offering flexibility, ease of maintenance, and suitability for a range of applications. Its design supports various installation scenarios and can handle different fluid types and pressures.

Reviews

There are no reviews yet.