Description

King Valves presents its meticulously engineered Y-Type Strainer, designed to deliver exceptional performance and reliability in industrial applications. Crafted with precision and quality, our Y-Type Strainer boasts robust construction to withstand the rigors of demanding environments.

Built from high-grade materials, our Y-Type Strainer ensures longevity and resilience against corrosion and wear, guaranteeing uninterrupted operation even in harsh conditions. Engineered with precision filtration capabilities, the Y-Type design effectively traps debris, particulates, and contaminants, safeguarding downstream equipment and processes.

Versatility is paramount. Our Y-Type Strainer is suitable for a wide range of fluids, including water, oil, gas, and various chemicals, making it a versatile solution for diverse industrial needs.

Designed for user convenience, the Y-Type Strainer facilitates hassle-free maintenance, with quick access to the screen for cleaning or replacement, minimizing downtime and optimizing efficiency. With its streamlined design and optimized flow path, our Y-Type Strainer ensures minimal pressure drop, promoting efficient fluid flow and maximizing system performance.

At King Valves quality and performance are our top priorities. Trust in our Y-Type Strainer to deliver unmatched reliability, efficiency, and value for your industrial operations.

What is a Y- TYPE STRAINER Used For?

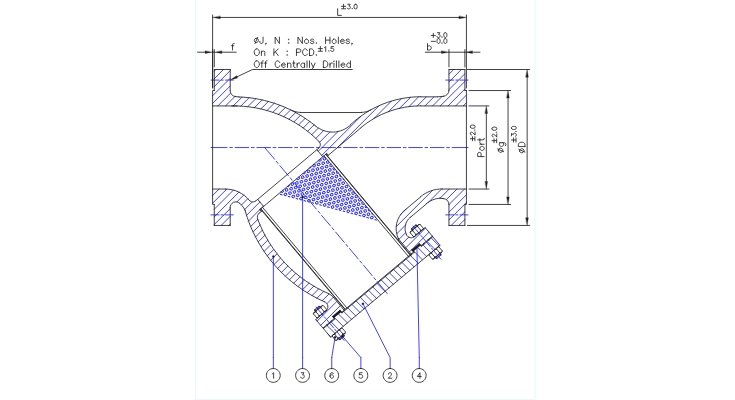

A Y-type strainer is a type of mechanical filtration device used in pipelines to remove unwanted solid particles from flowing fluids. It is shaped like the letter “Y,” hence its name. The strainer typically consists of a perforated or mesh-lined straining element housed inside a Y-shaped body with inlet and outlet ports.

Y-type strainers are commonly used in various industries such as oil and gas, petrochemical, water treatment, and manufacturing. They serve several purposes:

Flow Control

-

- Particle Removal: The primary function of a Y-type strainer is to trap and remove solid particles, debris, rust, scale, or other contaminants from the fluid stream. This prevents damage to downstream equipment such as pumps, valves, and meters.

- Protection: Y-type strainers act as a protective barrier for sensitive components downstream. By capturing debris and contaminants, they help extend the service life and efficiency of expensive equipment and machinery.

- Maintenance: Regular maintenance and cleaning of Y-type strainers are easier compared to cleaning equipment downstream. They can be easily removed from the pipeline for cleaning or replacement of the straining element.

- Flow Regulation: In some applications, Y-type strainers can help regulate flow by providing a certain degree of resistance to the fluid passing through. This can be useful for balancing flow rates or preventing excessive pressure drops.

Overall, Y-type strainers play a crucial role in maintaining the integrity and efficiency of fluid systems by ensuring that only clean and properly filtered fluids flow through the pipeline.

Reviews

There are no reviews yet.